Dodge Journey: Schematics and diagrams

40/41TE - WITH VARIABLE LINE PRESSURE

Fig. 181: Identifying Line Pressure - Park & Neutral

Fig. 182: Identifying Line Pressure - Reverse

Fig. 183: Identifying Line Pressure - First Gear (Drive)

Fig. 184: Identifying Line Pressure - Second Gear (Drive)

Fig. 185: Identifying Line Pressure - Second Gear EMCC (Drive)

Fig. 186: Identifying Line Pressure - Direct Gear (Drive)

Fig. 187: Identifying Line Pressure - Direct Gear EMCC (Drive)

Fig. 188: Identifying Line Pressure - Fourth Gear Overdrive (Drive)

Fig. 189: Identifying Line Pressure - Fourth Gear Overdrive EMCC (Drive)

SPECIFICATIONS

GENERAL SPECIFICATIONS

GEAR RATIOS

BEARING SETTINGS (END PLAY AND TURNING TORQUE)

CLUTCH CLEARANCES

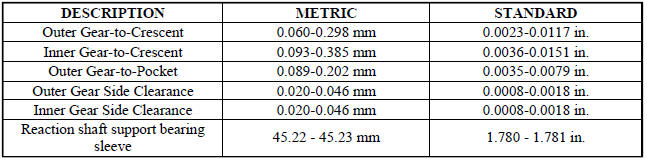

OIL PUMP CLEARANCES

INPUT SHAFT

TORQUE SPECIFICATIONS

SPECIAL TOOLS

Fig. 190: Puller C-637

Fig. 191: Pressure Gauge (High) C-3293SP

Fig. 192: Dial Indicator C-3339

Fig. 193: Oil Pump Puller C-3752

Fig. 194: Seal Puller C-3981B

Fig. 195: Universal Handle C-4171

Fig. 196: Seal Installer C-4193A

Fig. 197: Adapter C-4996

Fig. 198: Remover Kit L-4406

Fig. 199: Gear Puller L-4407A

Fig. 200: Bearing Installer L-4410

Fig. 201: Gear Checking Plate L-4432

Fig. 202: Bearing Puller L-4435

Fig. 203: Differential Tool L-4436A

Fig. 204: Special Jaw Set L-4518

Fig. 205: Installer L-4520

Fig. 206: Thrust Button L-4539-2

Fig. 207: Adapter L-4559

Fig. 208: Adapter L-4559-2

Fig. 209: Bearing Splitter P-334

Fig. 210: Puller Set 5048

Fig. 211: Remover/Installer 5049-A

Fig. 212: Installer 5050A

Fig. 213: Installer 5052

Fig. 214: Compressor 5058A

Fig. 215: Compressor 5059-A

Fig. 216: Installer 5067

Fig. 217: Pliers 6051

Fig. 218: Installer 6052

Fig. 219: Installer 6053

Fig. 220: Button 6055

Fig. 221: Plate 6056

Fig. 222: Disk 6057

Fig. 223: Installer 6061

Fig. 224: Remover 6062-A

Fig. 225: Holder 6259

Fig. 226: Bolt 6260

Fig. 227: Installer 6261

Fig. 228: Tip 6268

Fig. 229: Remover/Installer 6301

Fig. 230: Remover/Installer 6302

Fig. 231: Installer 6536-A

Fig. 232: Puller 7794-A

Fig. 233: End Play Socket Set 8266

Fig. 234: Input Clutch Pressure Fixture 8391

Fig. 235: Driveline Support Table 8874

Fig. 236: Driveline Support Fixture 8534B

Fig. 237: Steering Shaft Roll Pin Remover/Installer 6831A

Installation

Installation

Fig. 164: Removing/Installing Bellhousing Upper & Lower Bolts

NOTE: If transaxle assembly is being replaced or overhauled (clutch

and/or seal

replacement), it is necessary to perform th ...

Accumulator

Accumulator

DESCRIPTION

Fig. 238: Identifying Underdrive & Overdrive Accumulators

- RETURN SPRING

- UNDERDRIVE CLUTCH ACCUMULATOR

- SEAL RING (2)

- OVERDRIVE CLUTCH ACCUMULATOR

The 41TE underd ...

See also:

Diagnosis and testing

BATTERY CABLES

A voltage drop test will determine if there is excessive resistance in the

battery cable terminal connections or

the battery cable. If excessive resistance is found in the battery c ...

Specifications

2.7L ENGINE

GENERAL SPECIFICATIONS

CYLINDER BLOCK

PISTONS

PISTON PINS

PISTON RINGS

PISTON RING SIDE CLEARANCE

PISTON RING WIDTH

CONNECTING RODS

CRANKSHAFT MA ...

Removal, Installation

REMOVAL

WARNING: Disable the airbag system before attempting any steering

wheel, steering

column or instrument panel component diagnosis or service. Disconnect

and isolate the negati ...